The future is a

Sustainable innovation with state-of-the-art technology.

With a continuous focus on innovation and quality, Matias & Araújo develops exclusive textile knitted fabrics, for a selection of the most prestigious brands and global projects in the sector.

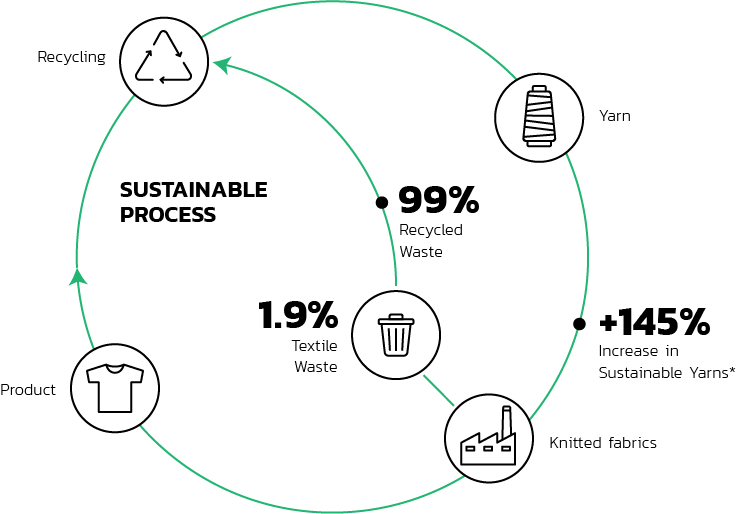

We are part of a circular economy

Matias & Araújo is part of a textile circle, which together with partner companies, transforms all its textile waste into new fibers.

*Increase registered in the acquisition of yarns with GRS, GOTS and BCI certificates, in the year 2021 compared to 2020. Estimate applied in the months of November and December, reflecting the annual average.

Recycling

All of our textile waste is separated and delivered to certified companies to proceed with its shredding.

Yarn

Using recycled and sustainable yarns, we develop new products that are increasingly more environmentally friendly.

Knitted Fabric

We develop innovative and high quality knits, using organic and recycled fibers.

Textile Waste

With a textile waste rate of just 1.9%, of which 99% are recycled, we continue to focus on improving these values.

Responsible

supply source

Certified commitment

Production based on quality and commitment.

We produce excellent custom circular knits. Backed by state-of-the-art industrial technology, with the best fibers and high-performance processes, which allow us to offer a wide range of services and products, with the highest quality and in reduced times.

Design and creativity.

We have a vast team of graphic designers, product designers and technicians specializing in circular meshes, who study each design and its behavior depending on each fiber and finish. We develop our own collection, with products of the highest technical and creative quality, as well as personalized designs at the client’s request.